Abrapa (Brazilian Cotton Producers Association) provides guidance through training, technical visits, and guidelines; ensures traceable origin results; and ensures credibility and transparency for HVI analysis results from Brazil’s instrumental classification laboratories.

With studies and advances in technology, Brazilian cotton presents the necessary level of quality to meet production demands, besides being totally free from contamination and being grown in high-yield areas, ensuring year-round supply.

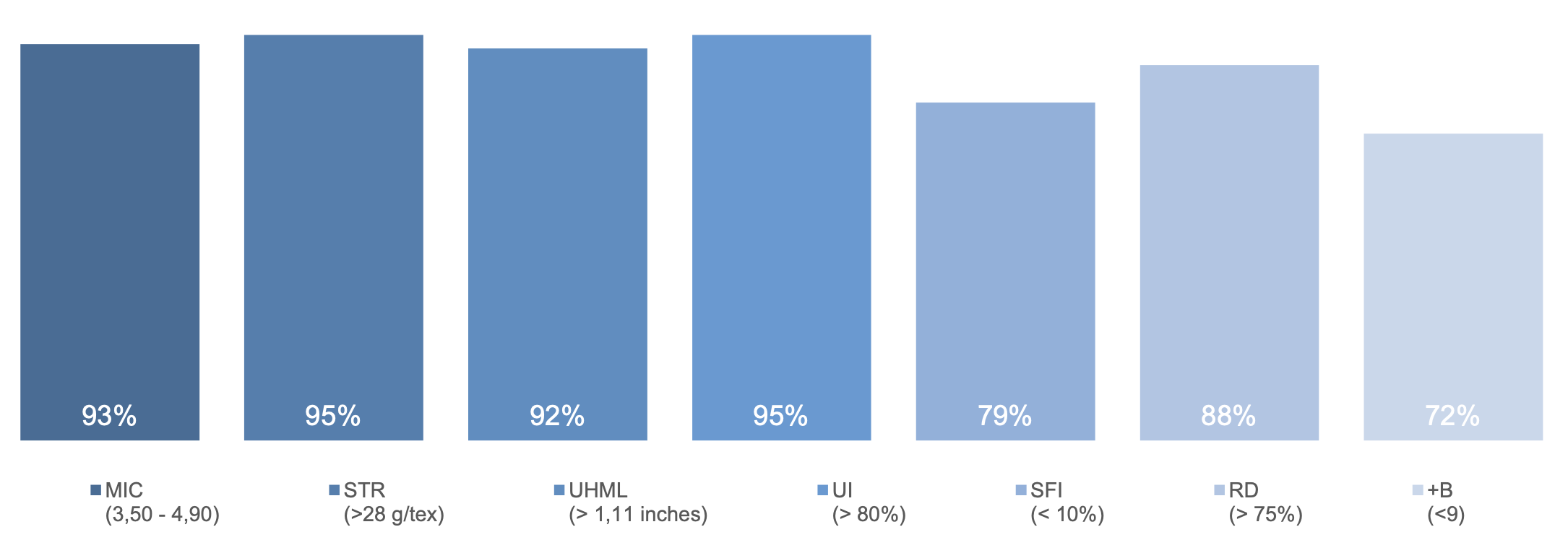

Source: SBRHVI Program. Update in October 2025 – 2025/2026 marketing year

Download our latest quality report:

The Cotton Brazil Knowledge Hub, a new feature of Cotton Brazil, is a global digital platform dedicated to advancing knowledge and transparency around Brazilian cotton.

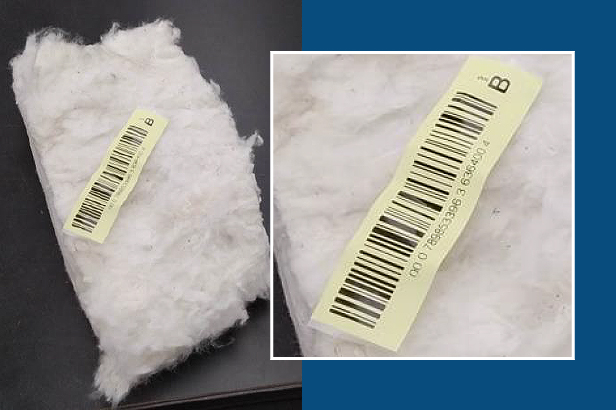

The SBRHVI system by Abrapa ensures that every single bale of Brazilian cotton is individually tested and identified. Each bale can be traced through a barcode or QR Code, providing instant and reliable access to quality data. From farm to spinning mill, Brazilian cotton travels with transparency, quality and trust.

The quality analysis process for Brazilian cotton is like a comprehensive “check-up” to ensure cotton reaches our clients in perfect condition.

One of the key steps in this process is the HVI (High Volume Instrument) analysis, which uses advanced technology to evaluate various cotton characteristics, such as strength, length, color, and purity. HVI analyzes large volumes of cotton with precision and speed, ensuring producers of the quality they’re harvesting and clients of the transparency and credibility of their purchases. When the sample arrives at the laboratory, it is conditioned, opened, and registered in the system before undergoing machine evaluation.

Samples are taken from each bale produced for HVI and visual analysis.

They are sealed in envelopes and sent to the classification room or laboratory. Once sealed, samples are tamper-proof and shielded from manipulation and contamination, ensuring process reliability.

Following the global reference standard, visual analysis can be conducted by the HVI testing lab, at the mill’s classification center, or in take-up rooms.

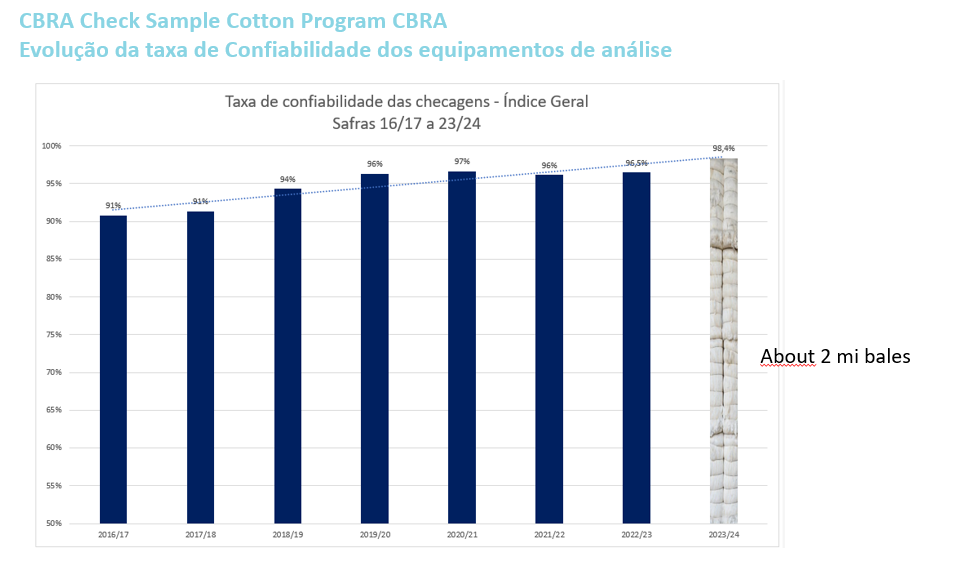

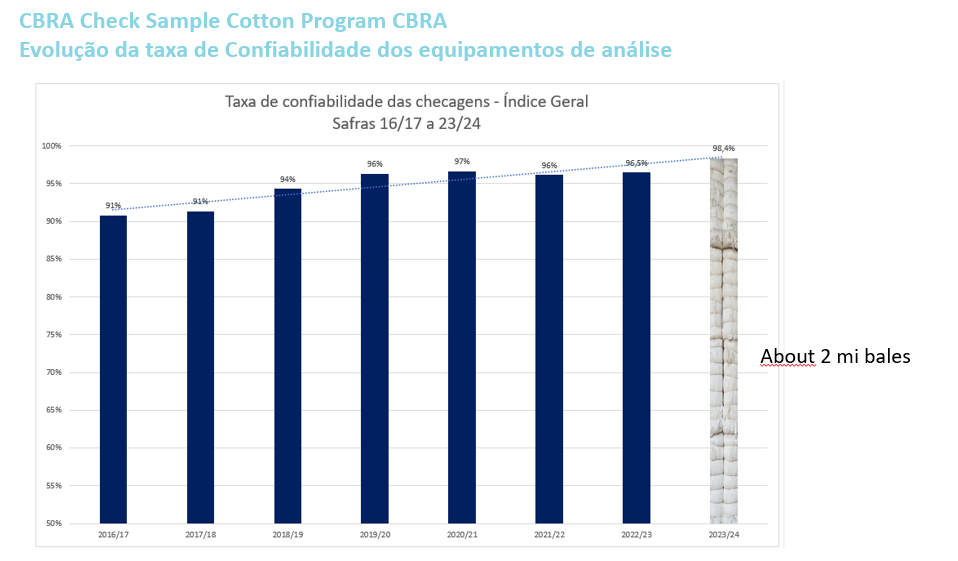

CBRA sends reference samples to laboratories, where teams perform reliable checks every 200 analyses. This procedure ensures results stay within acceptable tolerance ranges and maintain reproducibility across all instruments.

The high-volume instrument analysis measures 14 key characteristics essential to the industry, including UHML length, uniformity index, micronaire index, resistance in grams per tex, degree of reflectance (Rd), and degree of yellowness (+b).

Learn more about each item ranges and maintain reproducibility across all instruments.

In the last harvest, there were 12 analysis labs across 5 states, near Brazil’s main cotton-producing regions. They operate more than 80 HVI analysis machines with the capacity to test 100% of the national crop.

Since 2017, Brazil has a quality program to monitor all high-volume HVI-type instruments. The instruments are monitored by CBRA through check samples every 200 analyses performed on each instrument. Consequently, the reliability rate has grown with each crop, from 91% in 2017 to over 95% today. For example 2022/23 crop, 13,378,800 bales were analyzed.

Graphical user interface, App

Since 2023, Brazil has piloted a program to certify bales according to international quality standards. This initiative enables official certificates issued by the Brazilian Government, which inspects classification labs and ginneries, ultimately providing an official certificate from the Ministry of Agriculture for each approved bale.

The CBRA is certified by ICA Bremen and accredited by INMETRO’s General Accreditation Coordination based on the NBR ISO IEC 17025 standard for the following commercially reliable characteristics: micronaire index, UHML length, uniformity index, strength in grams per tex, reflectance degree, and yellowness degree, attesting to its technical competence.

Data is organized in an intelligent database accessible by QR Code or barcode, bale by bale.