Learn about the technologies employed by the Brazilian cotton industry

Brazilian cotton |

Innovations have been implemented in the last decades, boosting the quality of Brazilian cotton. Check out the main technologies currently applied in the field.

The technology used in the Brazilian cotton industry is recognized worldwide as one of the most advanced in the sector. Not surprisingly, Brazil currently ranks number 2 in global cotton exports and number 1 in the production of Better Cotton. A strong commitment to quality and tireless efforts put in managing increasingly sustainable farms have guided our work, with technology playing a key role in the process to ensure cotton production can thrive in a tropical environment.

100% Brazilian innovation

Today, our production is closely related to the evolution of technology, and one example is the possibility of having two crops in the same agricultural season. For this, we need selected varieties of soy and cotton developed by research institutions, machinery adapted to no-till planting, and good field and topographic conditions. This innovation is unique to Brazil and ensures high yields per hectare, combining row crops and cotton. Other cotton growing countries do not use this methodology.

Another big step towards sustainability are the bio-inputs. The use of biological control needs to be related to the integrated pest management process, which combines chemical, biological, and genetic control, and several studies are being done in this area. Brazil is also proud to pioneer this strategy.

However, the use of no-till planting is what stands out the most in relation to other countries, at it is the management method with the greatest penetration in Brazil. Preserving the soil without much tilling is a conservationist practice and needs to be well managed to ensure the longevity of its use. No-till farming has been related to higher carbon fixation, supporting soil improvement and increasing fertility and biological activity, all fundamental pillars for the sustainability of cotton crops, which demand good soil conditions.

The relationship between yield and technology

The technological evolution has been fundamental for the increase in yields, in addition to ensuring the financial health of farms.

Today Brazil leads the world in cotton yields in non-irrigated areas, also known as drylands. However, the tropical environment is challenging for production: soils need to be improved and natural conditions favor the proliferation of pests and diseases. In this scenario, the technology employed ensures that these challenges are overcome and that the operation remains profitable.

Besides yields, the technology used in Brazilian crops makes it possible for 60% of the planted area to have a second crop in the same agricultural year. Moreover, the average yield of Brazilian cotton is 1,800 to 1,900 kg of lint per hectare, with some growers harvesting up to 2,300 kg/ha. This result is only possible thanks to the use of state-of-the-art technology and constant investments in sustainability and innovation.

Main technologies used in the Brazilian cotton crop

Innovation has reached several farming segments, but today we will present some of the technologies that led to higher quality and sustainability levels in Brazilian cotton.

– High-tech seeds: the adaptation of cotton varieties to the cerrado environment seeks to ensure good yields in this planting environment and continuously improved fiber quality for buyers. Yield is also a fundamental factor in the economic balance of the business.

– No-till planting: reduces fuel consumption per hectare, reduces erosion and water loss to erosion, maintains the ideal temperature for the plants, improves biology, optimizes the use of fertilizers and chemicals, and increases organic matter and carbon fixation in the soil.

– Precision agriculture: encompasses technologies for the rational use of inputs, georeferencing, better distribution of plants in the soil, targeted control of pesticides, soil mapping for decision making, and information control centers for machines.

– Bio-inputs: farms and state cotton institutes were the promoters of the use of bio-inputs in Brazil. As the environment in the country is quite challenging in terms of pest pressure, bio-inputs are a complementary technology to help understand its dynamics while respecting the environment. It is a fundamental tool for integrated control. Biofactories are installed in producing farms – the so called On-Farm facilities.

– High technology in pesticide application: the use georeferencing, traps for monitoring pests (including in the off-season), high-precision sprayers that turn nozzles on and off individually, and low flow rates minimize losses and ensure greater effectiveness in the use of pesticides. Aerial application has been complemented with drones, which allows protection to adjacent ecosystems, bee hives, other neighboring crops, cities, rivers, and lakes.

– Weather stations on the farms: identify the best period for pesticide application and minimize water loss in irrigation by evaporation, monitor and anticipate the risk of fires, and monitor ideal conditions for the proliferation of diseases and pests.

– 100% mechanical harvesting: standardizes the cotton to be harvested, reduces fiber contamination and brings better working conditions for farm workers.

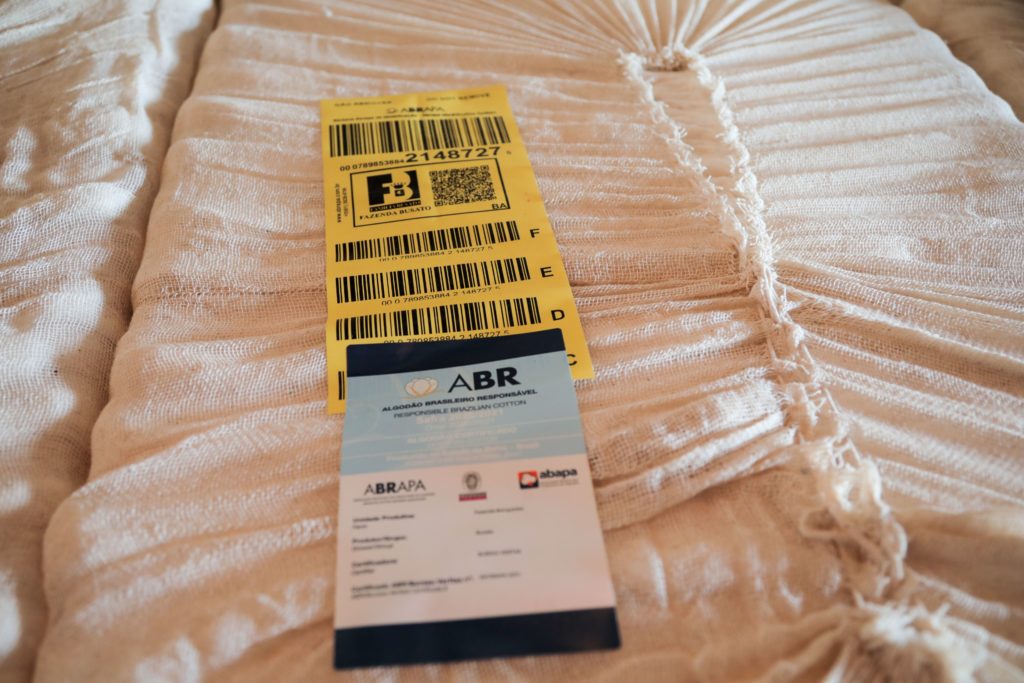

– Farm level ginning: In Brazil, ginning takes place in plants located in the farms. These are high-investment ginning plants that ensure standardization, quality, traceability, and delivery to the end consumer.

– Use of renewable energy – many farms have invested in solar energy generation.

– Qualification of the labor force – constant promotion of professional development so that workers can make the best use of new technologies in the field, with course offerings on good working conditions and agricultural practices.

In the chart below, it is possible to see the evolution of the Brazilian cotton industry compared to other cotton growing countries in the world. Technological innovation was the main drivers for the last two decades of intense growth and development, with quality and sustainability.