From Seed to Fiber: The Stages of Cotton Plant Development

Brazilian cotton |

Cotton is much more than just a raw material in our daily lives. Before a cotton product reaches your routine, it goes through a fascinating transformation process in the field. Today, we’ll show you how the cotton plant develops, a process that can vary significantly depending on factors such as the cultivar type, climate (especially water availability and temperature), and soil conditions (such as fertility).

In general, this maturation period lasts between 140 and 220 days. In the Cerrado region (MT, BA, GO, MS, MG, MA, PI, TO), the cycle is usually slightly shorter, ranging from 180 to 200 days.

Each stage of this cycle plays a crucial role in ensuring the quality of the fiber that reaches our hands. Join us on this journey!

The Beginning of Cotton Plant Development

Everything starts with sowing, which takes place between December and February, depending on the region and the type of cultivation—whether it’s the main crop or a second crop.

At this stage, cotton seeds are carefully placed in fertile soil, where they await germination and the start of their journey to becoming high-quality cotton fibers.

Emergence: Welcome!

Emergence occurs 5 to 7 days after sowing, when the seed absorbs water from the soil and begins to develop. This is when the seedling emerges from the ground, marking the start of its growth. Even at this early stage, the plant starts forming its first roots and leaves, preparing for the next phases of its development.

A Green Field Begins to Appear

After emergence, the cotton plant’s initial growth is slow, but around 50 days after sowing, it starts developing more rapidly.

At this point, floral buds begin to appear (around day 40) and continue forming until approximately day 140. The cotton plant develops gradually, from the base to the top.

The field turns green between 80 and 100 days, with plants reaching about 1 meter in height. At this stage, the cotton plant is full of reproductive structures like floral buds, flowers, and bolls, which are essential for fiber production.

Flowers Everywhere!

Cotton flowers start blooming around 60 days after sowing and continue appearing until day 150.

Initially, the flowers are white or cream-colored, but after pollination, they turn a vibrant pink. This color change is a distinctive characteristic of Brazilian cotton (Gossypium hirsutum), unlike Gossypium barbadense, whose flowers are usually yellow.

Flowering is essential for the formation of cotton bolls, which will later contain the fibers to be harvested.

Fruit Development

Between 70 and 180 days after sowing, cotton bolls begin to form and mature, marking the plant’s peak reproductive cycle. These rounded structures house the fibers that will be harvested later.

During this stage, the plant channels its energy into ensuring the bolls grow to their full size and quality.

The White Field

Around 160 days after sowing, the cotton bolls start opening, revealing the soft, white fibers—raw cotton.

This moment is known as the “white field” and lasts up to 200 days after sowing. When the bolls open (now called “capsules”), it indicates that the cotton is ready for harvest.

At this final maturation stage, harvesting begins once most of the bolls are open and dry, ensuring the fibers are collected at their optimal quality.

Harvest Time

Harvesting takes place between June and September, depending on the region and variety planted.

At this stage, it is crucial to ensure that most of the bolls are open to collect mature, high-quality fibers. Dry periods are ideal to avoid excess moisture, which can compromise the cotton’s quality.

Ensuring Cotton Quality

After harvesting, seed cotton moves on to processing, where fibers are separated from the seeds and go through cleaning and technical adjustments to ensure quality.

Laboratory Analysis

As mentioned earlier, controlling moisture levels is essential for maintaining cotton quality. For example, if cotton is too dry, the fibers may break, increasing the number of short fibers. On the other hand, if it has too much moisture, the ginning process becomes more difficult, reducing efficiency. Therefore, monitoring moisture levels throughout the process is crucial for smooth production and the right fiber quality.

Additionally, ginning and cleaning equipment must be adjusted according to the type of cotton being processed. These adjustments prevent seed coat fragments from contaminating the fiber and help reduce the short fiber index.

Another key factor is the maintenance of brushes and grids in the equipment, ensuring effective cleaning while preserving fiber yield and quality.

Proper Storage and Traceability

After processing, proper storage is essential to maintain cotton quality. Bales (compressed cotton units for transport) should be stored in dry, well-ventilated locations away from moisture and pests.

The best practice is to use outdoor storage yards, placing bales on platforms and covering them with tarps. It’s also important to maintain proper spacing between bales, as advised by insurance providers.

To ensure transparency throughout the process, every processed batch is recorded, allowing full traceability of the cotton—from its origin to its processing details and fiber characteristics. This increases product confidence and market value.

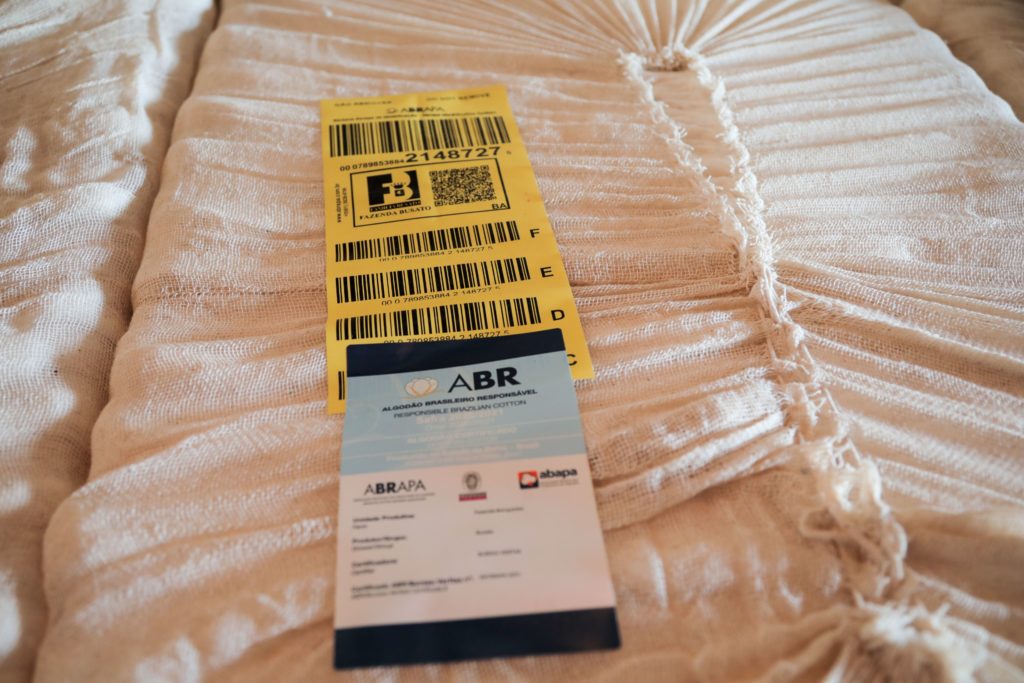

Speaking of which, did you know that Brazilian cotton is traceable, bale by bale? Textile industry professionals receiving our bales can access origin data through a label or QR Code attached to each bale.

Learn more about this process HERE. 🌱💚